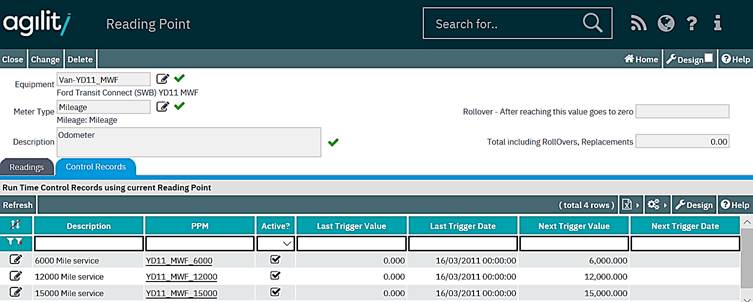

Control Records (Run time PPM)

Each reading point can have associated control records. This is accessed from the control record tab on the reading point details form.

The control record contains all attributes for the generation of PPM jobs based upon usage and is used as the reference point for generation. It also contains a log of jobs generated as well as a log of usage.

Multiple control records can be held against each reading point allowing the generation of PPM jobs on different cycles.

The form also contains functionality allowing a reading point to be changed whilst maintain the run time history.

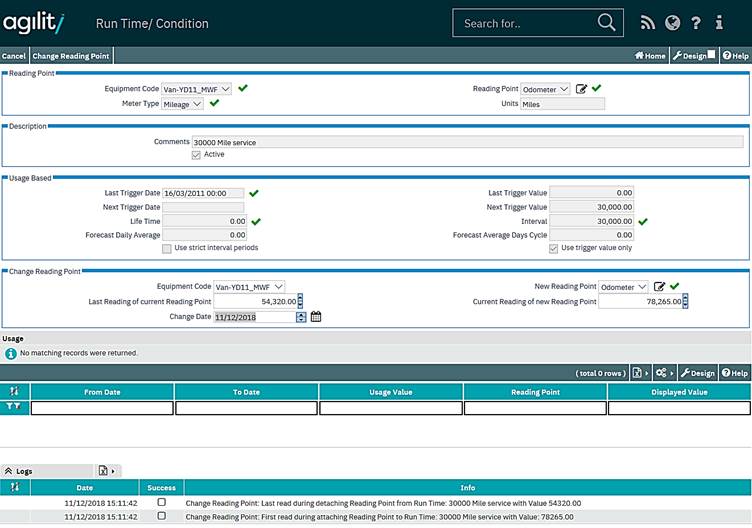

Reading Point Box

Equipment Code

The equipment code of the equipment the reading point is associated with

Meter Type

The type of meter, (see Standing Data: Equipment -> Meter Types for more information about Meter Types)

Reading Point

This is the name of the reading point.

Units

This is the unit of measure for the meter, taken from the meter definition.

Description Box

Comments

Free text field for adding additional information about the reading point.

Active

Check box determining if this particular control record is active. If the control record is not active, then PPM’s will not be generated from this control record.

Usage Based Box

Last Trigger Date

Last Date/time at which a PPM was generated from this control record

Next Trigger Date

Next Date/time at which a PPM will be generated based upon usage.

Life Time

This figure represents the overall life time of the equipment to which this reading point has been associated.

For example:

Using a car and gearbox scenario:

If we have 2 cars, one has done 20000 miles and the other 30000 miles. We also have a brand new gear box. We fit the gear box to one car and do 10,000 miles in the car, the gear box is then swapped to the other car. The car containing the gearbox has done 30000 miles but the life time reading of the gear box would still only be 10000. So the PPM to service the gearbox would still be based upon the gear box usage and not the car containing it.

Last Trigger Value

This is the value at which the last PPM job was triggered.

Next Trigger Value

This is the value at which the next PPM job will be generated.

Interval

This is the factor that determines when a job is triggered. The figure represents the cycle in the unit of measure at which to generate a job.

So for example if we have an interval of 100, every time the usage reaches or exceeds intervals of 100 a job will be generated.

Forecast Daily Average

This figure represents a calculated average value of the amount of usage for each day.

Forecast Average Days Cycle

This figure represents the value in number of days, based upon usage, at which the interval will be hit and a job triggered.

For example, if the interval was set to 100 and usage was 100 per day then this value would be 1.

Change Reading Point

The change reading box allows a reading point to be changed for a different one but still maintain the run time history for the equipment item to which the reading point has been associated.

Equipment Code

The equipment code to which the reading point is to be associated

New Reading Point

The new reading point to be associated with the equipment item

Last Reading of Current Reading Point

This is the last reading taken of the existing reading point prior to it being removed from the equipment item.

Current Reading of New Reading Point

This is the reading of the new reading point taken when the item was attached to the equipment item but prior to any usage.

Change Date

This is the date at which the change took place, so that new readings are taken from this date onwards.

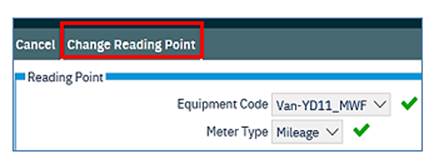

To change the reading point, click the ‘Change Reading Point’ Option in the toolbar.

Two logs are maintained at the bottom of the form, and these are displayed as grids.

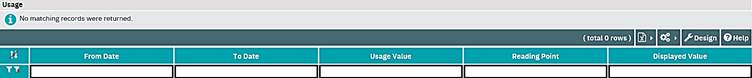

Usage

The usage grid shows usage by show the period between the pervious and current reading point and the reading value.

From Date

This is the will be the date the last reading was taken. (or the previous ‘To Date’).

To Date

This is the date the reading was taken and forms the ‘From Date’ of the next reading.

Usage Value

This is the meter reading that was entered on the ‘To Date’ and represents the usage for the period ‘From Date > ‘To Date’.

Meter Point

The name of the reading point.

Logs

This displays a time and date stamped activity log of this particular control record in reference to the PPM. Showing when the PPM was triggered, when runtime values were re-calculated and changes to the control record.