Stock Replenishment

Ref: AG3_401

Description

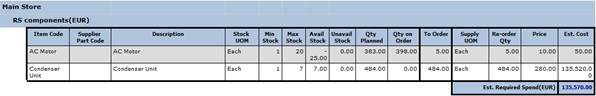

This is an operational report used as part of the stock replacement process. It generates a tabular report organised by store location and then by preferred supplier if available.

It contains data on current stock levels and projected stock demand with the quantities and costs required to meet the required stock level.

It will also display a warning if orders for any particular store have been suspended.

The Report Returns

Store (Store name)

Preferred Supplier (if available)

Item Code (Inventory item code)

Supplier Part Code

Description (Inventory item description)

Stock UOM

Min Stock (Minimum stock to be held for this item)

Max Stock (Maximum stock to be held for this item)

Avail Stock (Current available stock)

Unavail Stock (Current stock unavailable or allocated)

Qty Planned (Current demand for item in item UOM)

Qty on Order (Current quantity on order for item in item UOM)

To Order (Quantity required to meet demand)

Supply UOM (UOM that the item is supplied in. Supply UOM may be different to issue UOM)

Re-Order Quantity

Price

Est. Cost (Based upon price per unit)

Operational Criteria

The report will return all stock inventory items that require stock to be order and that meet the filter criteria selected.

Filters

• Inventory Item Range Filter

• Store Range Filter

• All Suppliers

o If this option is checked then the report will not filter out any suppliers. If the option is unchecked then a Supplier Range Filter will become enabled.

Grouping Options

• Category

o Category of inventory item

• Section

o Section from inventory item

• Sub-Section

o Sub-section from inventory item

Aims

The report is designed to facilitate easier stock management and the ordering process. The report also contains a ‘Generate Purchase Orders’ function which will automatically generate purchase orders based upon selected criteria.

Results Analysis

This is an operational report that is used as part of the stock replenishment process. Please refer to the ‘Stock replenishment’ section of inventory help for more information.