Inventory Usage

Ref: AG3_404

Description

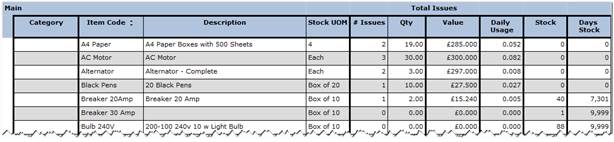

The report provides a tabular grid grouped by store, which details inventory item usage by showing the number of issues, the value of issues and the average daily usage figure.

The Report Returns

Category (Inventory item category if applicable)

Item Code (Inventory item code)

Description (Inventory item description)

Stock UOM (UOM for inventory item)

# Issues (Total number of issues in the specified date range)

Qty (Total quantity of items issued in the specified period)

Value (Total value of items issued within the specified period)

Daily Usage (Calculated average daily usage)

Stock (Current quantity in stock)

Days Stock

Operational Criteria

The report will return all inventory items where there has been an issue within the specified date range and that meet the filter criteria selected.

Filters

• Date Range

o This will include any inventory items that were issued between these dates.

• Inventory Item Range Filter

• Store Range Filter

• Supplier Range Filter

Grouping Options

• Category

o Category of inventory item

• Section

o Section from inventory item

• Sub-Section

o Sub-section from inventory item

Calculations

All calculations are based upon transaction that occurred within the period.

|

Field |

Calculation |

|

#Issues |

Number of Issues – Number of returns |

|

Qty |

Quantity Issued – Quantity Returned |

|

Value |

Value of issues – value of returns |

|

Daily Usage |

(Quantity Issued – Quantity Returned) / Number of days in the date range |

Aims

The report is designed to help identify which inventory items are being used the most and which are being used infrequently, and the associated material cost.

Results Analysis

Any items where the value issued is high should be looked into with a view to finding a better price to help reduce costs. High volumes of issues of the same item should also be looked into to see why so many are being used.

High usage of a particular part or item could indicate a failing in the production process or maintenance schedule.